Multivariable (MIMO) Kit

Description

Introducing the Multivariable Kit, a comprehensive experimental setup designed for advanced control systems analysis and implementation. This versatile kit combines essential components including a linear actuator, load cell, and three encoders, along with two DC motors, providing a dynamic platform for exploring a wide range of multidimensional control strategies. The linear actuator enables precise linear motion control, while the load cell allows for accurate force measurement and feedback. With three encoders, users can capture rotational position and velocity data from various points within the system, facilitating detailed analysis and closed-loop control algorithms. Additionally, the inclusion of two DC motors expands the kit's capabilities, offering opportunities for studying complex multi-input, multi-output (MIMO) control systems. Whether used for educational purposes or advanced research, the Multivariable Kit empowers engineers and researchers to delve into the intricacies of multivariable control theory and applications with confidence and precision.

Objective

The Multivariable Kit aims to provide a comprehensive platform for the study and implementation of advanced control systems. It enables precise control and analysis through multidimensional strategies by integrating various key components. The objective is to enhance understanding of multivariable control systems, facilitating detailed exploration of both theory and real-world applications. This kit is designed to serve both educational and research purposes, offering tools for high-level control analysis.

Method

The kit combines essential components such as a linear actuator for precise motion control, a load cell for force measurement, and three encoders for capturing rotational position and velocity data. It also includes two DC motors, enabling complex multi-input, multi-output (MIMO) control experiments. Users can develop closed-loop control algorithms by leveraging the real-time data collected from the encoders and sensors. The system allows for comprehensive feedback control, supporting advanced control techniques and strategies.

Practical Applications

This kit is useful in educational settings where students can explore fundamental and advanced concepts in multivariable control theory. Researchers can apply it to analyze and develop control algorithms for complex systems. The system’s capability to model and control MIMO systems makes it ideal for industrial applications that require precise motion and force control. Additionally, it is valuable in real-world scenarios such as robotics, automation, and any field involving dynamic system analysis.

Key Features

The Multivariable Kit includes a linear actuator for accurate linear motion control and a load cell for precise force feedback. Three encoders are used to capture detailed rotational data, supporting the development of closed-loop control systems. The kit also features two DC motors, expanding its functionality to explore complex MIMO systems. The combination of these components creates a versatile experimental platform for advanced control systems.

Learning Outcomes

Users will gain hands-on experience with multivariable control systems, including MIMO strategies. They will learn how to implement and analyze feedback control using real-time data from encoders and load cells. The kit enables the exploration of closed-loop control algorithms and the application of these concepts to complex, dynamic systems. Participants will also develop an understanding of how to control and measure multiple inputs and outputs within a single system, enhancing their skills in control theory.

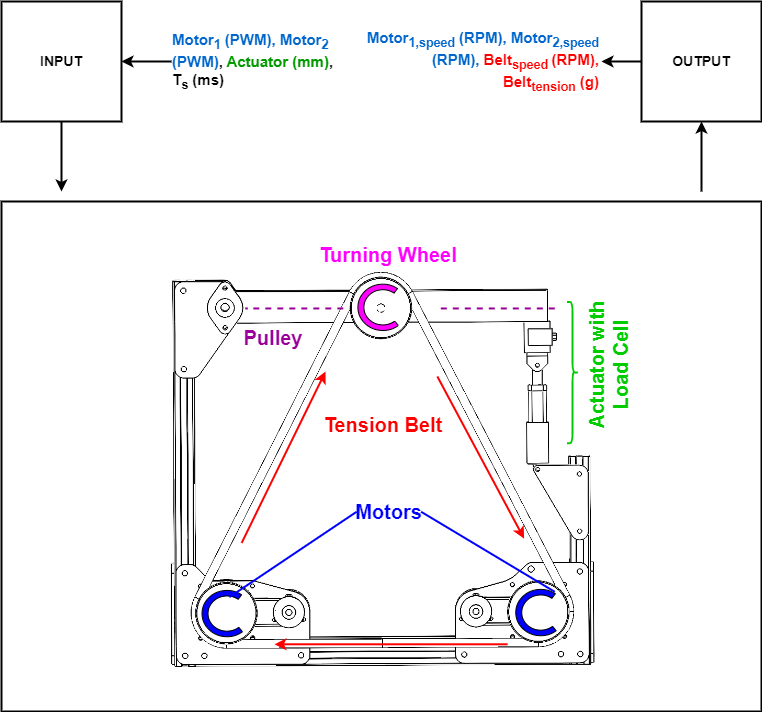

Functional In/Out Diagram

The functional diagram above illustrates the main components of the system and their interactions:

Input: The inputs to this system include control signals for the two motors, Motor1 and Motor2, in the form of PWM (Pulse Width Modulation) signals. These signals regulate the speed and torque of the motors, ensuring precise control over the movement of the system. Additionally, the actuator's displacement in millimeters is another input parameter that allows for adjustments to the belt's tension. These inputs enable dynamic manipulation of the mechanical components to achieve the desired performance.

Process: The process begins with the motors driving the system by interacting with the tension belt. The motors apply force through the pulleys and turning wheel to control the movement of the belt. An actuator with a load cell is integrated into the system to measure the tension applied to the belt in real-time. As the motors rotate, the belt speed and tension are influenced by the motor speeds (Motor1 speed and Motor2 speed) and the actuator's displacement. The load cell provides feedback on the belt tension, allowing for continuous adjustments to maintain optimal operation. This ensures smooth and efficient mechanical performance.

Output: The outputs of this system include the rotational speeds of Motor1 and Motor2, the speed of the belt, and the tension applied to the belt. These outputs are crucial for monitoring the system’s performance in real-time. By providing precise data on motor speeds, belt speed, and tension, the system allows for accurate control and evaluation of its efficiency and stability. This feedback mechanism ensures that the system operates reliably under varying conditions.

Posted on 2024-12-02 12:52:55

The "Multivariable Kit" has been added, offering a comprehensive platform for advanced control systems analysis and implementation. This kit includes a linear actuator, load cell, three encoders, and two DC motors, allowing for precise motion control, force measurement, and the study of complex multidimensional control strategies. Ideal for both educational and research purposes, it provides a robust setup for exploring multivariable control systems with confidence!