BLDC Motor Kit

Description

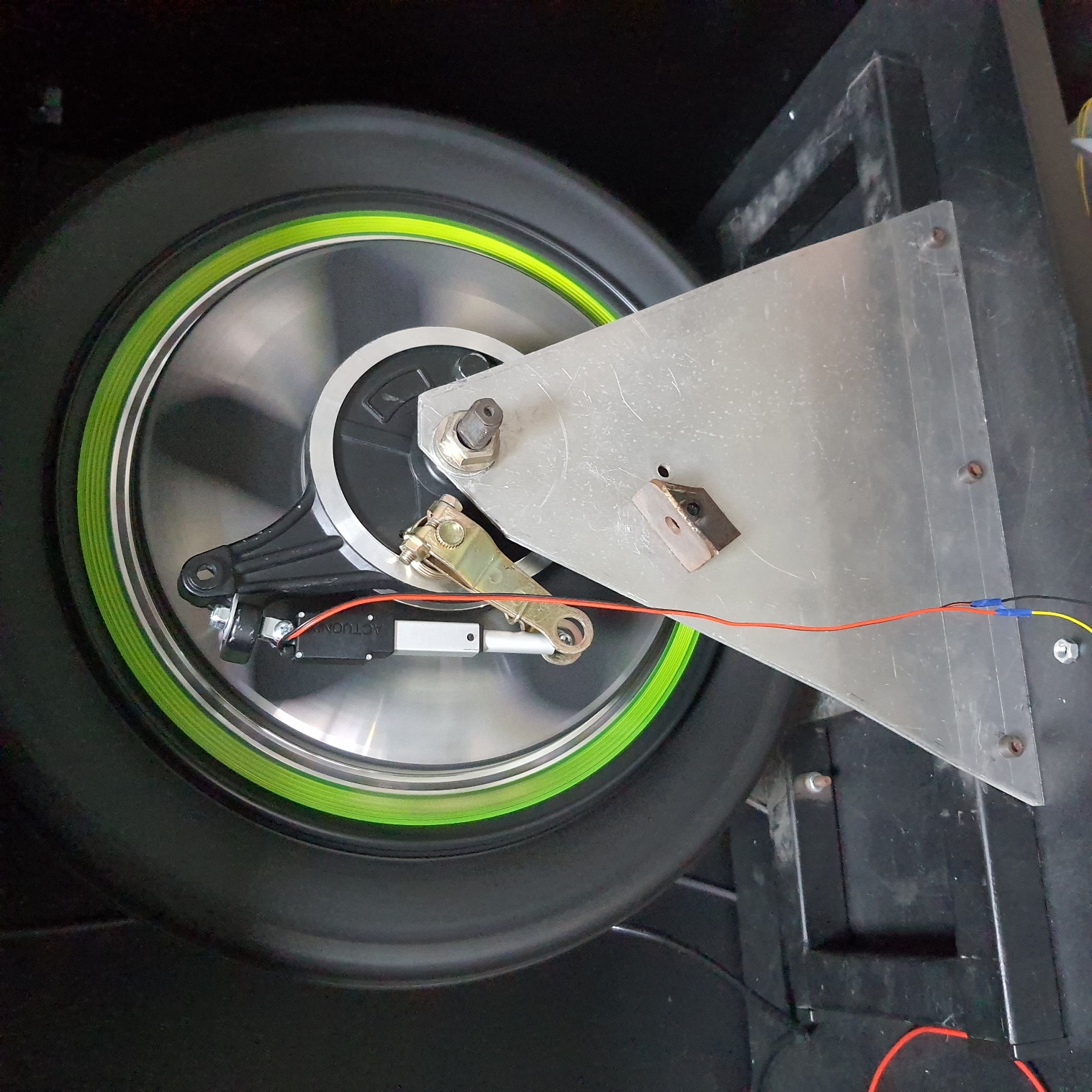

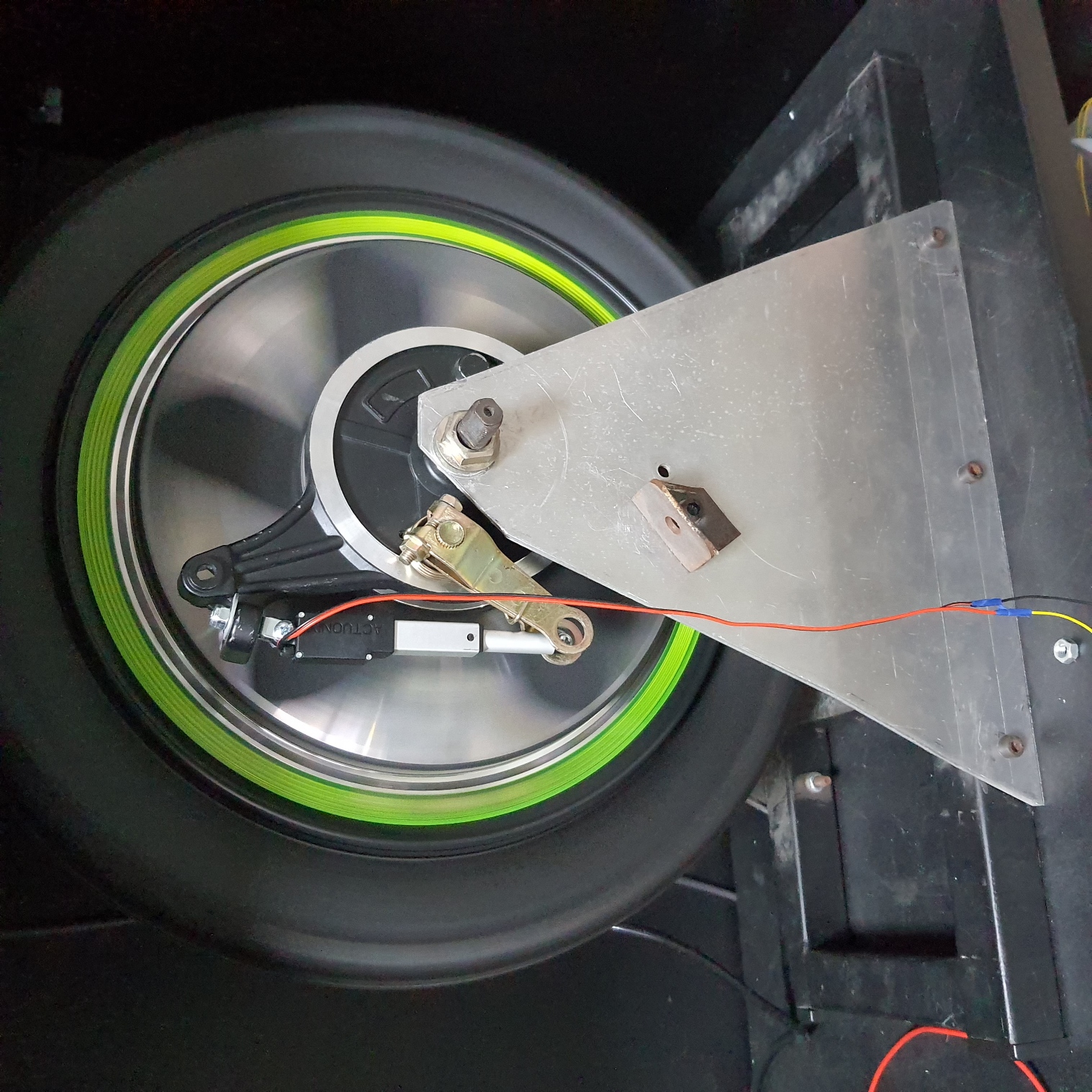

This innovative laboratory setup provides the capability to conduct experiments on a brushless DC (BLDC) motor remotely, eliminating the need for physical presence in the laboratory. The project is centered around the real-time control and monitoring of the BLDC motor's speed using a closed-loop control system. The closed-loop system ensures precise speed regulation by continuously comparing the motor's actual speed with the desired setpoint and adjusting the control inputs accordingly. This setup allows users to gain hands-on experience with fundamental concepts in motor control, such as feedback mechanisms, control system design, and parameter tuning, all within a virtual environment. By leveraging online accessibility, this lab not only enhances convenience but also fosters collaborative learning and research opportunities. It serves as a versatile platform for exploring the dynamics of BLDC motors and testing various control strategies, making it ideal for educational purposes, skill development, and advanced experimentation.

Objective

The primary objective of this laboratory is to provide a versatile remote platform for understanding and implementing the control of a Brushless DC (BLDC) motor. By enabling users to experiment with closed-loop control systems online, the lab aims to bridge the gap between theoretical knowledge and practical application, making advanced motor control accessible without requiring physical presence in a laboratory environment.

Method

The experimental setup utilizes a secure online interface that allows users to remotely connect to and interact with the BLDC motor system. A closed-loop control mechanism forms the core of the system, ensuring precise speed regulation by continuously comparing the actual speed of the motor to a user-defined setpoint and adjusting the control inputs accordingly. Users can modify key control parameters, such as those in proportional-integral-derivative (PID) controllers, and immediately observe the impact on system behavior through real-time feedback displayed on the interface. This iterative process facilitates a deeper understanding of motor dynamics and control.

Practical Applications

This remote lab setup has wide-ranging practical applications across various fields. In industrial automation, it mirrors the control mechanisms used in robotics, conveyor systems, and other motor-driven processes. It provides insights into the operation of BLDC motors, a critical component in electric vehicles, enabling participants to explore strategies relevant to automotive engineering. In the aerospace sector, the setup mimics motor control in drones and UAVs, while in renewable energy systems, it supports the study of motor-driven solutions like wind turbines and solar trackers. These applications make the lab a valuable resource for both academic research and professional skill development.

Key Features

The lab offers several key features designed to enhance the user experience and learning outcomes. Remote accessibility allows users to engage with the experimental setup from anywhere, fostering flexibility and inclusivity. Real-time monitoring provides live feedback on critical motor performance parameters, such as speed, current, and voltage, which users can analyze for optimization and troubleshooting. The system supports customizable control algorithms, allowing users to implement and test their own strategies, including advanced PID or adaptive controls. An intuitive, interactive interface ensures ease of use, while the scalability of the platform enables the integration of additional sensors or components for expanded experiments.

Learning Outcomes

Participants in this lab will develop a comprehensive understanding of BLDC motor dynamics and the principles of closed-loop control systems. By engaging with real-time experimentation, they will master the implementation and tuning of feedback mechanisms, gaining skills directly applicable to real-world problem-solving. The ability to analyze and optimize system behavior through data interpretation will enhance their proficiency in data-driven decision-making. Furthermore, the lab provides practical experience that prepares users for applications in industries such as automotive, aerospace, and renewable energy, equipping them with the expertise needed for advanced engineering challenges.

Functional In/Out Diagram

The functional diagram above illustrates the main components of the system and their interactions:

Input: Details will become.

Process: Details will become.

Output: Details will become.

Posted on 2024-12-04 14:31:58

The "Remote Experimentation Platform for BLDC Motor Control" has been introduced, offering an accessible and innovative solution for hands-on learning in motor control systems. This lab enables users to remotely experiment with a brushless DC motor, featuring a closed-loop speed control mechanism for precise performance evaluation. By providing real-time feedback and customizable control parameters, this platform facilitates a comprehensive understanding of motor dynamics and feedback control principles.