Fluid Dynamics Kit

Description

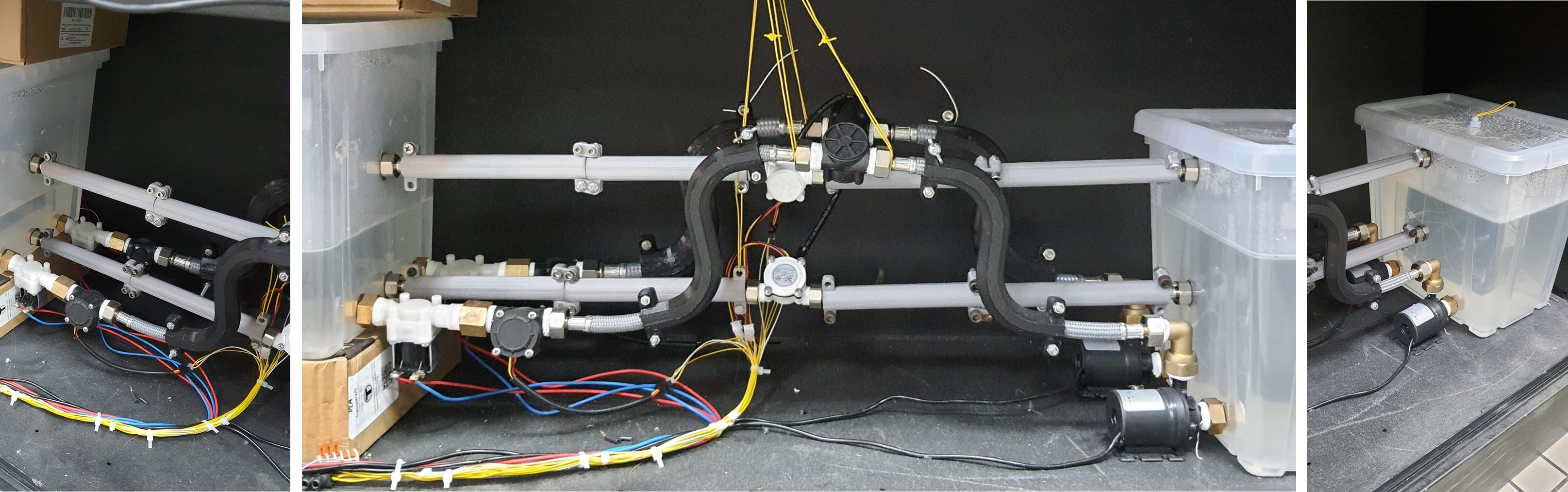

The experiment explores fluid dynamics by focusing on Bernoulli’s and Torricelli’s principles. It involves a setup with two interconnected tanks and four pipelines. Two of the pipelines are designed to demonstrate Torricelli’s principle, showcasing the behavior of fluid flowing from a height difference of 12 cm. The other two pipelines illustrate Bernoulli’s principle, featuring different diameters (DN8 and DN13), each equipped with water flow sensors to monitor the flow rate. Adjustable velocity pumps control the fluid flow, allowing researchers to investigate how varying conditions impact fluid behavior. The experiment provides a practical platform to analyze and understand the theoretical and empirical aspects of fluid dynamics.

Objective

Understand Fluid Dynamics: Gain insight into the interaction between fluid flow and Bernoulli’s and Torricelli’s principles. Analyze Fluid Behavior: Examine how different factors such as flow rate, pressure, and pipe diameter influence fluid behavior. Explore Real-World Applications: Investigate practical applications and implications of fluid dynamics principles in engineering and physics.

Method

Setup Preparation: Assemble the two interconnected tanks and four pipelines, ensuring two pipelines are configured to demonstrate Torricelli’s principle and two for Bernoulli’s principle. Equip each pipeline with water flow sensors. Adjust Flow Rates: Utilize the two adjustable velocity pumps to control and vary the flow rates through the pipelines. Data Collection: Record measurements from the flow sensors under different conditions to assess the effects of varying flow rates, pressure differences, and pipe diameters. Analysis: Compare the collected data against theoretical predictions for Bernoulli’s and Torricelli’s principles. Analyze how variations in experimental conditions impact fluid behavior. Practical Application: Explore and discuss practical scenarios where the principles of fluid dynamics can be applied.

Practical Applications

Engineering Design and Optimization: Pipe and Pipeline Design: Understanding the effects of varying pipe diameters and flow rates on fluid behavior helps in designing more efficient pipelines and conduits in various engineering applications. Pump and Valve Systems: Insights into how different flow rates and pressures affect fluid dynamics can lead to the optimization of pumps and valves for improved performance and energy efficiency. Hydraulic Systems: Water Distribution Networks: The principles studied can be applied to the design and management of water distribution systems, ensuring optimal flow and pressure in municipal water supplies. Hydraulic Machinery: Knowledge of fluid behavior under different conditions aids in the design of hydraulic machinery used in industries, such as construction and manufacturing. Environmental Engineering: Flood Management: Understanding how fluids behave in different scenarios helps in the design of flood control systems and drainage solutions. Wastewater Treatment: The experiment’s principles can be applied to improve the efficiency of wastewater treatment processes by optimizing flow and pressure in treatment plants. Aerospace and Automotive Industries: Aerodynamics: Insights from Bernoulli’s principle are crucial for designing aerodynamic shapes for aircraft and vehicles, improving fuel efficiency and performance. Fluid Dynamics in Engines: The study of fluid flow in pipelines is relevant for the design of efficient fuel and cooling systems in automotive and aerospace applications.

Key Features

Dual-Tank System

Utilizes two interconnected tanks to facilitate the study of fluid dynamics in a controlled environment.

Four Pipelines Configuration

Torricelli Pipelines

Two pipelines demonstrate Torricelli’s principle with a height difference of 12 cm, illustrating fluid behavior under gravitational effects.

Bernoulli Pipelines

Two pipelines with different diameters (DN8 and DN13) represent Bernoulli’s principle, showing how varying pipe diameters affect fluid pressure and velocity.

Water Flow Sensors

Equipped with sensors to measure the flow rate of water, allowing for precise data collection and analysis of fluid behavior.

Adjustable Velocity Pumps

Two pumps with adjustable speeds to control and vary the flow rate of the fluid through the pipelines, providing flexibility in experimental conditions.

Empirical and Theoretical Analysis

Provides a platform for both theoretical study and empirical investigation, bridging the gap between fluid dynamics principles and practical applications.

Data Collection and Monitoring

Enables real-time monitoring and recording of fluid flow data to enhance understanding and analysis of fluid dynamics.

Real-World Applications

Illustrates practical applications of Bernoulli’s and Torricelli’s principles in engineering and physics, highlighting their relevance in real-world scenarios.

Comprehensive Experimental Setup

Designed to offer a thorough exploration of fluid dynamics principles, including pressure, flow rate, and diameter effects on fluid behavior.

Learning Outcomes

Theoretical Understanding

Develop a clear understanding of Bernoulli’s and Torricelli’s principles and their implications in fluid dynamics.

Practical Skills

Gain hands-on experience in setting up fluid dynamics experiments, controlling flow rates, and using flow sensors for data collection.

Analytical Abilities

Enhance skills in analyzing fluid behavior, comparing experimental results with theoretical models, and understanding the impact of different factors on fluid dynamics.

Application Knowledge

Apply fluid dynamics principles to real-world problems, recognizing the significance of these principles in engineering and scientific contexts.

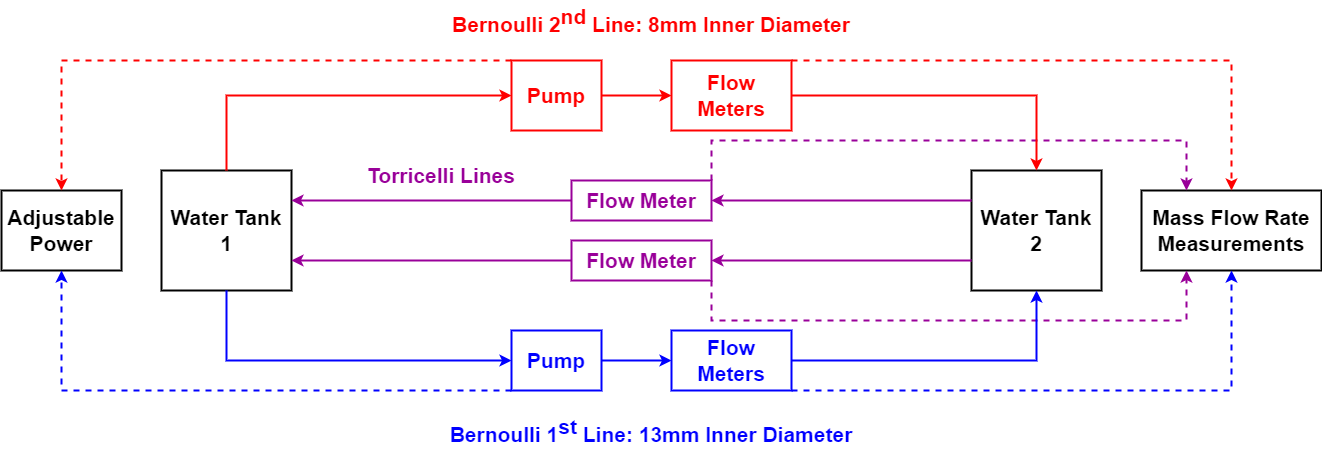

Functional In/Out Diagram

The functional diagram above illustrates the main components of the system and their interactions:

Input: Input elements include the adjustable power source, which regulates the energy supplied to the pumps, and the initial water levels in the tanks, which can be manipulated to set specific experimental conditions. The system allows for control of flow rates through pumps and variations in pipe diameters, enabling exploration of Bernoulli's and Torricelli's principles.

Process: In the Process stage, water is pumped through two different pipelines, characterized by varying inner diameters (13 mm and 8 mm), which influence flow rates and pressure distributions. Flow meters located in both pipelines measure the real-time flow rate, while additional flow meters on the Torricelli lines provide further data about how pressure and height differences impact flow dynamics. The water moves cyclically between Tank 1 and Tank 2, facilitated by the pumps, maintaining a controlled circulation within the system.

Output: The Output of the system is a comprehensive set of data collected from the flow meters and mass flow rate measurements. These outputs include parameters such as flow velocity, mass flow rate, and pressure changes within the system, which can be used to validate theoretical principles like Bernoulli's and Torricelli's equations. This data provides insights into fluid behavior under different conditions, supporting both educational and research objectives.

Posted on 2024-12-04 15:16:07

We are excited to announce the release of our latest laboratory experiment focused on fluid dynamics! This new lab provides an in-depth exploration of Bernoulli and Torricelli principles through a hands-on approach.